HOME

|

the binding of… E N C L O S U R E S: T I M E S A N D P L A C E S

A fairly chronological but far from comprehensive account of a long, long journey undertaken without a reliable map. Not really for those with a life. See the completed binding here.

|

||

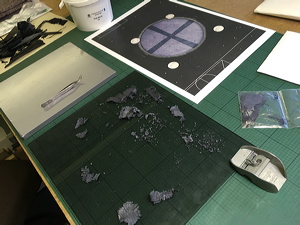

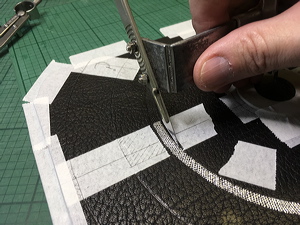

Preparing a palette of monochrome feathered parings for the lacunose strap. Note original design printout. |

Lacunose for strap with superimposed cutting template |

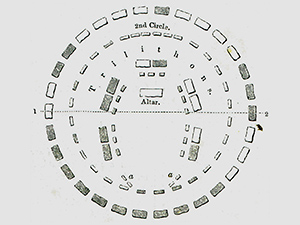

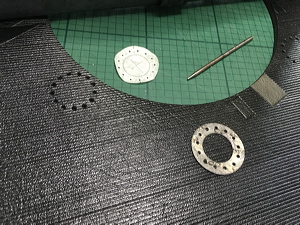

Plan of Stonehenge |

Stylised Stonehenge design for inner covers |

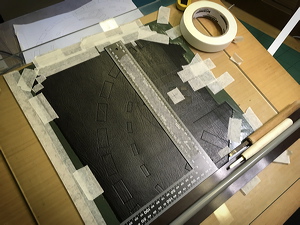

Tooling parallel lines around inner cover design elements. |

Tooling parallel lines around inner cover design elements. |

Inking stonework design on the dyed Tyvek wrapper. |

Perforating the wrapper to aid folding the concertina. |

Cutting the rather tediously shaped lacunose strap, which required… |

…an unwieldy improvised cutter. |

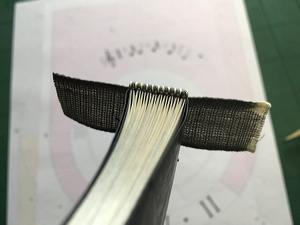

Applying dyed sewing tape over the temporarily-sewn concertina in preparation for sewing endbands. |

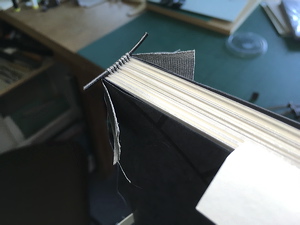

Sewing endband with dyed thread over rolled leather core. |

Sewing endband with dyed thread over rolled leather core. |

Sewing endband with dyed thread over rolled leather core. |

Completed endband. White loops are an extension of the first stage sewing. |

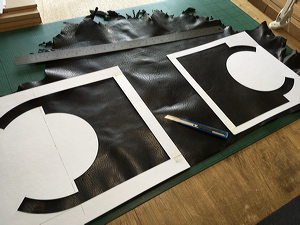

Cutting the outer laminate from a beautiful skin of Harmatan Nigerian goatskin. |

Various printed templates. |

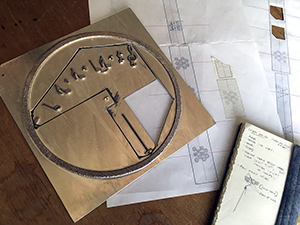

Roman numeral hand tools on loan from Trevor Lloyd. |

Sewing templates/notes and magnesium block. |

Crosshatched ring blocked in silver foil (rear cover). |

Crosshatched ring blocked in silver foil (front cover). |

Blinding circles with a farthing wheel. |

Blinding circles with a farthing wheel. |

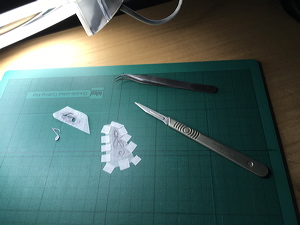

Cutting very thin leather onlays. |

Cutting very thin leather onlays. |

Applying onlays into blocked impressions before blocking again to consolidate. |

Applying onlays into blocked impressions before blocking again to consolidate. |

Clockface onlays. |

Removing the surface leather in preparation for the sewing holes. |

Inserting rings of alum-tawed goatskin into the consolidated impressions. |

Cutting out the laminated covers. |

Cutting out the laminated covers. |

So far, so good. Phew! |

Punching the sewing holes through the inner laminate. |

Lacunose strap opened up to facilitate second stage sewing. |

Second stage sewing. |

Second stage sewing. |

Second stage sewing. |

Second stage sewing. |

Closing the lacunose strap. |

Completed sewing. |

Punching holes for the parchment donuts that will secure the cover straps. |

Sewing the cover straps with silver wire. |

Sewing the cover straps with silver wire. Note brain switch in 'off' position during this operation. |

Still sewing. |

Silver wire - tricky stuff. |

Making the lacunose buttons. |

Making the lacunose buttons. |

Completed buttons. |

Opening the cover foredges to insert carbon rods for rigidity. |

Opening the cover foredges to insert carbon rods for rigidity. |

Inserting magnets into the polypropylene stand. |

Inserting magnets into the polypropylene stand. |

Cutting the Tyvek-covered foamboard box inserts. |

'Snake coffin' box walls. |

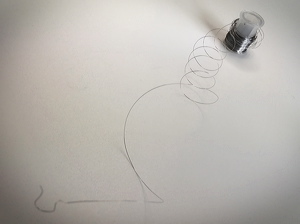

Assembling Windmill paper fragments for stonework design. |

Assembling Windmill paper fragments for stonework design. |

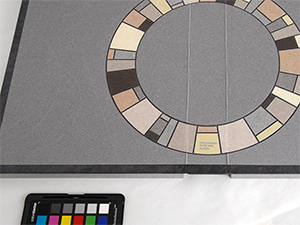

Coating cut 'stones' with gloss gel. |

Looks relatively simple, doesn't it? It was actually by far the most testing and tedious part of the entire production. Never again! |

|